Selected products were added to comparison

See products on comparison page

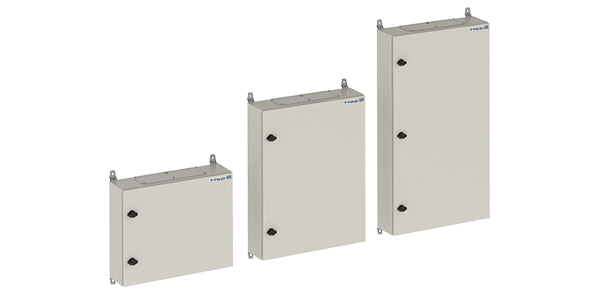

Representative Image Only

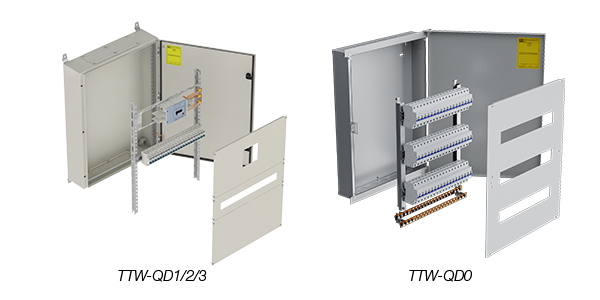

Designed for all types of needs, the TTW01-QD switchgear assists in embedded and overlapping installations up to 630 A. Safety, robustness, flexibility and agility are characteristics that define the design of these frames. They are manufactured in accordance with the requirements of NBR IEC 61439 and according to Regulatory Standard 10 - NR10.

Main benefits

- Simplified installation and operations;

- Unique reliability of totally tested panels;

- Robust and compact structure;

- In compliance with the applicable safety standards.

Tests

According to NBR IEC 61439-1 and NBR IEC 61439-3 standards (which are complementary), for an electrical panel to be considered TTA/PTTA, it must undergo type tests and routine tests so as to ensure its electromechanical performance.

NBR IEC 61439-1 standard deals with panels in general, and NBR IEC 61439-3 standard (for applications in environments with non-qualified people) exclusively addresses panels up to 250 A and short circuit limited to 10 kA rms or 17 kA peak value.

Applications

Developed to ensure quality, safety and stability in the electric energy distribution of your business, WEG totally tested distribution panels are prepared to face all types of demand. With innovative technology and modern design, the TTW01-QD is ideal for your requirements.

Guarantee of performance

- Metallic panels in a single set, allowing faster assembly and more robustness in handling and maintenance;

- The panels are tested with load in order to assess their thermal performance and heat dissipation capacity;

- Short circuit tests ensure the operation safety of the panels, preventing people from being exposed to risks during an abnormality in the electric operation;

- Removable flanges on top and bottom of the panel simplify the entry and exit of cables, conduits and cable trays, without contaminating internal parts of the panel.

Flexibility and agility in the assembly

- Panels in different sizes and depths;

- Finish in light Gray RAL 7035;

- Modularity and interchangeability of assembly kits between TTW01-QD electrical panels;

- Wide range of assembly kits, allowing a great variety of arrangements;

- Casters that allow moving the assembly rack, simplifying cable entry and exit;

- Versatility for special assemblies, without using standardized kits by means of blank mounting plates;

- Mobile racks that allow the assembly of the components out of the panel. Such characteristic allows the panel frame to go to the customer/site, while the panel builder installs the electric components on the rack. After that task is completed, it is just necessary to install the rack in the panel already sent to the site;

- MakeTTW software that allows the fast sizing and definition of all the parts that compose the panel;

- Agility in the replacement or complement of pieces and parts of the panel;

- Latches that can fit a padlock in order to lock the panel door, as required by the NR10 Brazilian standard;

- Supply of panels assembled or split into structure, rack and door;

- The busbars are made of electrolytic copper (99.9% pure) and tin plated with a minimum thickness of 8 µm.

- Assembly kits made of galvanized steel plates.

Restricted Area

Login and password are supplied for the customers who took the training and signed a partnership agreement with WEG.

- Training Documents

- TTW Columns and Boxes Manuals

- Labels

- TTW Bulletin

- Kit Tables

- TTW01 Boxes and Columns – 2D Drawing

- Thermal dissipation

- Videos