Selected products were added to comparison

See products on comparison page

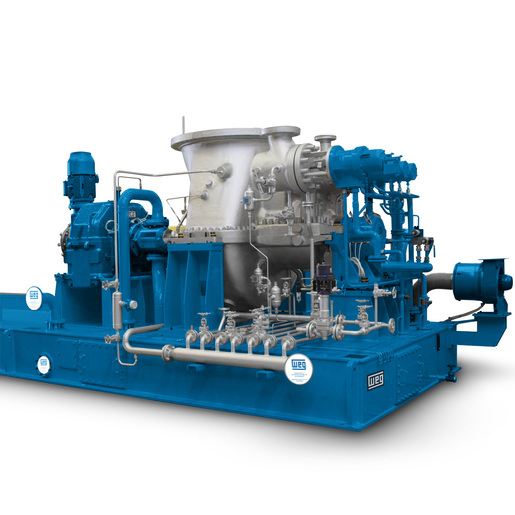

Representative Image Only

WEG steam turbines, TMC and TMCE lines, are condensing type and built with impulse technology. They have multiple stages and are available with or without controlled extraction. These turbines operate under maximum conditions of 652 psia (45 bara) inlet steam pressure, 842°F (450 °C) inlet steam temperature and can generate up to 17 MW. The TMC and TMCE steam turbine lines are used to generate electricity, applied in thermal power plants, sugar & ethanol, pulp and paper, petrochemical, among others.

Technical Characteristics

- Impulse tecnology and multi-stage

- Condensing with or without controlled extraction

- Nominal power output up to 17 MW

- Inlet pressure up to 652 psia / 45 bar(a)

- Inlet temperature up to 842 °F / 450 °C

Comprehensive, integrated and smart solution

With a comprehensive range of products and solutions tailored for steam power generation and mechanical drives, WEG designs, manufactures, and installs steam turbines, gearboxes, generators, as well as control and automation panels. All the components are designed using advanced technology and adhere to rigorous international quality standards. The steam turbines are available for various industrial segments and operate with steam derived from diverse sources like biomass, biogas, natural gas, heat recovery, waste-to-energy, and more.

Segments:

- Food and Beverage

- Pulp and Paper

- Cement

- Corn Ethanol

- Wood

- Mining

- Oil, Gas and Petrochemicals

- Waste-to-energy

- Steel

- Sugar-energy

- Thermal power plants

- Others

What is a Steam Turbine?

It is a machine that extracts thermal energy from the steam and converts it to mechanical work on a rotating shaft. The thermal energy is converted into kinetic energy through the expansion of the steam inside the turbine. The steam flows through properly designed fixed blades (stator) and moving blades (rotor) so that, according to the principles of impulse or reaction, they can efficiently transfer energy to the turbine shaft. During the expansion, there is a change in enthalpy due to the decrease in pressure and temperature of the steam, as well as the increase in its specific volume. Depending on the flow rate, this results in a certain power output on the shaft. Thus, the mechanical energy generated on the turbine shaft allows for the drive of various types of rotating equipment, such as fans, pumps, mills, compressors, and also 2 or 4-pole generators for electricity production. WEG has its own technology for the design and manufacture of impulse and reaction steam turbines, with an output power of up to 150 MW. The turbine frames are available in single or multiple stages, backpressure and condensing, with or without controlled extraction, and can operate with superheated or saturated steam.