Selected products were added to comparison

See products on comparison page

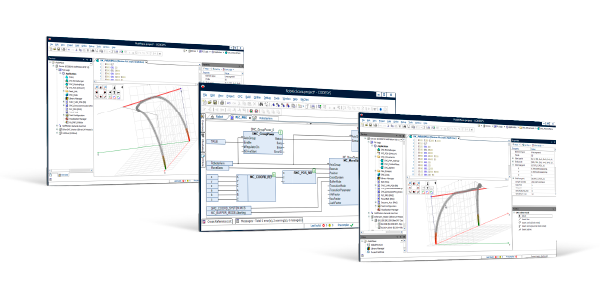

Representative Image Only

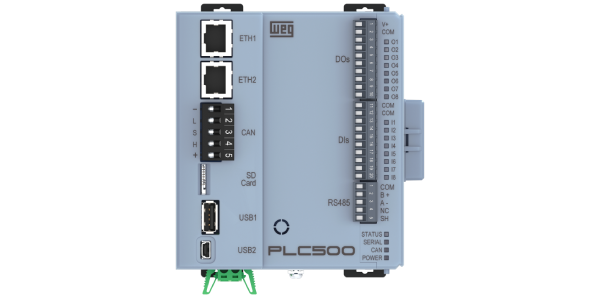

High-tech - Excellent cost-benefit

- Powerful IMX Dual Core 1GHz processor + Coprocessor @240MHz;

- RAM / Flash Memory: 1GB / 4GB;

- Extremely compact and modular design;

- Digital Inputs / Digital Outputs: 8 / 8 (PNP);

- 4 x inputs up to 150 kHz;

- Protocol support: CANopen / Modbus RTU / Modbus TCP / Ethernet-IP / EtherCAT / Profinet;

- IoT Protocols (MQTT);

- Micro SD Card Input;

- USB Host input;

- USB Host port for Programming;

- 2 x Gigabit Ethernet ports;

- Supports up to 08 local expansions.

Flexibility above all

Developed to be a PLC of fast integration to the factory environment and easy expansion, PLC500 shares the same expansion cards used in the line of WEG RUW100 Remote Units. Thus, you purchase a card and can use it in different WEG products, that is FLEXIBILITY.

All expansions are made through the Plug and Play concept, Simple, Fast and Efficient.

Expand Your Needs

The expansion cards used in PLC500 line have numerous configurations and allow the user to enjoy better combinations to meet his demands. Extremely compact design, only 25 mm per card. The cards are found in 10 different versions, featuring digital inputs and outputs, analog temperature inputs (Thermocouple J/K/T, PT100 and PT1000), and universal analog inputs and outputs in 0 to 10V and 0/4 to 20 mA.

Compact and Rugged

Developed to be a compact device to occupy the minimum space possible, also taking into account all the robustness required in an industrial equipment, that is PLC500. Built to meet IP20 protection degree and 5 - 150 Hz vibrations with maximum amplitude of 7 mm.

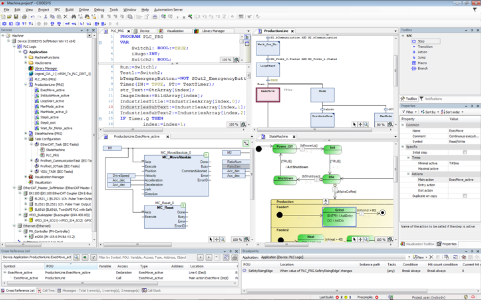

Development of high-level solutions

Develop your solutions in PLC500 through the CODESYS ® programming platform and enjoy the best development tools through object-oriented programming. This ensures that the developer can create their solutions more efficiently, saving time and accelerating their Startup.

This global programming platform allows the user to create, simulate, and debug the complete solution, bringing more integration and agility to the day-to-day.

Access the download center and download the updated version of CODESYS ®.

International Programming Standard

Develop your solution from a platform created following international programming standards (IEC61131-3). CODESYS is programmable from the five main languages currently used and an additional one (CFC).

- Ladder (LD);

- Block Diagram (FBD);

- Function Graphical Sequencing (SFC);

- Structured Text (ST);

- Continuous Function Chart (CFC).

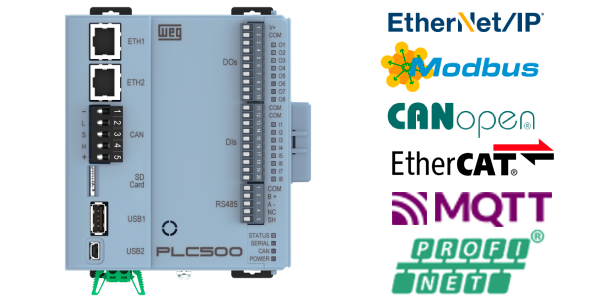

Variety of protocols

To ensure easier integration into different communication networks, PLC500 was designed to meet the main and most used communication protocols in industrial environments such as CANopen, Modbus (RTU and TCP) and Ethernet/IP, EtherCAT, MQTT and Profinet.

Be in control of movements

The PLC500MC version is the Motion Controller dedicated version, designed to offer the maximum in performance in machines and systems that require precise movements control.It combines high performance for control of embedded IoT IoT resources, allowing the integration of complex systems also in cloud.

With its powerful hardware, it is able to control up to 32 real or virtual axles, simple or synchronized, allowing its use in a wide range of applications and with different levels of complexity.

Tecnologia de movimento

- Biblioteca com blocos para controle de eixos, manipulação e processamento de caminhos CNC, grupos de eixo, além de transformações cinemáticas populares.

- Editor came integrado

- Editor CNC 3D integrado de acordo com DIN 66025 (G-Code)

- Configurador de grupos de eixos para diferentes cinemáticas

- Fácil comissionamento de eixos (Online Configuration Mode)

- Blocos de função certificados de acordo com PLCopen MotionControl, Part 1 (V20)

- Blocos de função certificados de acordo com PLCopen MotionControl Part 4 (movimento coordenado)

- Decodificador de G-code, incluindo suporte para subprogramas e expressões em G-code

- Blocos de função para testar velocidades de transição

- Blocos de função para leitura e processamento de caminhos CNC de arquivos (para caminhos criados e processados externamente)

Connectivity and ioT tools that add value to the operation

Developed especially for machine manufacturers (OEMs), the PLC500ED is developed for work in complete harmony with the digital platform Wegenology and Weg Smart Machine, platforms of WEG based on cloud computing that allows OEMs to follow the performance and operation of their machines from anywhere in the world.

The PLC500ED together with one of the two WEG digital platforms, allow manufacturers of equipment, add more services and functionality to your equipment being some of it as: remote assistance and operating alerts through configurable alarms, maintenance schedules, among other services, always respecting the business rules established on a case by case basis between the manufacturers and their customers.

Make your production processes digital

Turn your processes and equipment digital through the WEG Smart Machine (WSM) smart digital platform. Get operational reports, create KPIs, optimize your resources, create custom alarms and much more.