Selected products were added to comparison

See products on comparison page

Representative Image Only

The ADL500 family is composed of three lines: ADL550, ADL530, and ADL510. Designed to meet the demands of high, medium, and low-rise building applications, not to mention the building retrofit market. The new ADL500 series also offers the latest in functional safety, energy savings, and connectivity.

Complete range of product for LIFT

The ADL500 family comprises three product lines: ADL550, ADL530 and ADL510.

Designed to meet the diverse demands of high, medium, and low-rise building applications, as well as the building retrofit market.

The range extension includes three product lines, four mechanical sizes, and 14 power sizes, spanning from 1.1 to 45 kW.

The new ADL500 series integrates cutting-edge functionality, safety features, energy efficiency, and advanced connectivity.

ADL510 - Low rise elevators and modernization

Designed to be easy to install and simple to startup,

ADL510 is the most suitable solution for low-rise and

low-demanding elevators in new buildings and modernization.

Typically used in open loop with asynchronous motors, it

offers also the possibilty to manage simple closed-loop

geared systems with integrated digital encoder interface

Power

- ADL510-4: 3ph x 400 V (-15% +10%) 50/60 Hz

Power Range

- ADL510-4: 4-22 kW

Features

- Motor type: Geared motors (asynchronous)

- Control mode: Sensorless Scalar control (SSC), Field-Oriented Control CL (Asyn FOC)

- Encoder: digital incremental and sinusoidal interface (TTL / HTL)

- Overload: 183% x 10 s at 0 Hz

- Switching frequency: 10 kHz

- Communication: Modbus TCP

- Rescue operation: UPS or batteries

- 4 wizards: setup, startup, optimization, troubleshooting

- Certifications: CE, ASME, CSA, EAC, RCM, EN81-20, EN81-50

ADL530 - Medium rise elevators

Designed to be compatible with all common machine room or MRL elevators with Geared or Gearless traction systems. ADL530 introduce into the elevator industry new concepts for communication and simplicity of use directly addressed to meet users needs in terms of performance and time saving. Universal encoder interface allow to have only one integrated interface to connect all most used encoders with relevant benefits for your stock, order process and commissioning. In addition the built-in multifunction USB and Wi-Fi communcation allow to simply configure your drive with a pendrive or your mobile phone.

Power

- ADL530-4: 3ph x 230-400-460-480 V (-15%+10%) 50/60 Hz

- ADL530-2T: 3ph x 200-230 V (-10%+10%) 50/60 Hz

Power Range

- ADL530-4: 4-45 kW

- ADL530-2T: 5.5-22 kW

Features

- Motor type: Geared and Gearless

- Control mode: Sensorless Scalar Control (SSC), Field-Oriented Control CL (Asyn FOC, Syn FOC)

- Encoder: universal encoder

- Overload: 183% x 10 s at 0 Hz

- Switching frequency: 10 kHz

- Communication: Modbus TCP, CAN (Standard CANopen and CANopen DS 417)

- Smart communication: USB and Wi-Fi

- Rescue operation: UPS or batteries

- 4 wizards: setup, startup, optimization, troubleshooting

- Certifications: CE, ASME, CSA, EAC, RCM, EN81-20, EN81-50

ADL550 - High rise and high demanding elevators

Specifically designed for elevators requiring high levels of performance with advanced safety features. ADL550 with enhanced overload up to 200% at 0 Hz and ambient temperature up to 50°C with no derating meets most demanding installations and harsh environments. Even in safety ADL550 goes beyond elevator industry standards adding to the Phase Contactorless (with STO SIL3) the ultimate Brake Contactorless (with Electronic Safe Brake Control SIL3).

Power

- ADL550-4: 3ph x 230-400-460-480 V (-15%+10%) 50/60 Hz

- ADL550-2T: 3ph x 200-230 V (-10%+10%) 50/60 Hz

- ADL550-2M: 1ph x 200-230 V (-10%+10%) 50/60 Hz

Power Range

- ADL550-4: 4-45 kW

- ADL550-2T: 5.5-22 kW

- ADL550-2M: 1.1-5.5 kW

Features

- Motor type: Geared and Gearless

- Control mode: Sensorless Scalar Control (SSC), Field-Oriented Control CL (Asyn FOC, Syn FOC)

- Encoder: universal encoder

- Overload: 183% x 10 s at 0 Hz

- Switching frequency: 10 kHz

- Communication: Modbus TCP, CAN (Standard CANopen and CANopen DS 417)

- Smart communication: USB and Wi-Fi

- Rescue operation: UPS or batteries

- 4 wizards: setup, startup, optimization, troubleshooting

- Safety: Phase Contactorless (STO SIL3), Brake Contactorless (with EBC500 Electronic Safe Brake Control SIL3)

- Ambient temperature: up to 50°C with no derating

- Certifications: CE, ASME, CSA, EAC, RCM, EN81-20, EN81-50

SMART CONNECTIVITY

USB

- Motor DataBase upload

- Parameter files upload and download

- FW updates

- Drive set-up

EtherNet Port

- Modbus TCP protocol ready for IoT

- Suitable for local PC direct connection or LAN integration

Wi-Fi

- Simple and Smart communication with your mobile phone

- WEG Liftouch APP full responsive and available for all operating system

CANopen Port

- Standard CANopen

- CANopen Lift DS417

- Open for customization with elavator control card protocol

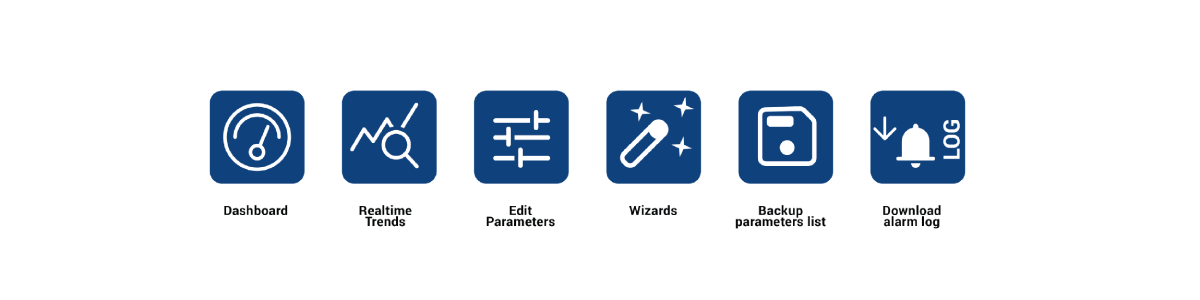

WEG LIFTOUCH

Connect to your ADL500 with WEG Liftouch APP

The WEG Liftouch app is used to interface locally via Wi-Fi or from remote through WEG Drives RMS portal to the ADL500 Elevator drive.

The WEG Liftouch app has the capability of viewing, editing parameters, creating backup parameter lists, downloading alarm logs.

In addition, the APP can be used for diagnostics and troubleshooting, I/O status and fault history.

WEG Liftouch APP is full responsive in order to adapt to any device format (mobile phone, tablet or laptop) and it is available for all operating systems Android, iOS and Windows.

Local Wi-Fi access with WEG Liftouch App

- Monitoring Dashboard

- 4 user levels password protected

- Start-up and Troubleshooting wizard

- Full parameter access

- Fast files sharing

Remote access and Cloud Service

- Fleet management on WEG Cloud Portal

- Remote monitoring with WEG Liftouch APP

- On line support

- Same features as local access

UNIVERSAL ENCODER

The ADL530 and ADL550 have an integrated HW interface to manage multiple encoders.

Encoder configuration can be simply set via SW with a dedicated parameter and selection list including all the most common encoders used in elevator application (SinCos, EnDat, SSI, BiSS, Digital Incremental).

Integrated Universal encoder leads to multiple advantages from ordering codes reduction, no need to stock expansion cards for each encoder type and no effort to mount them on the drive.

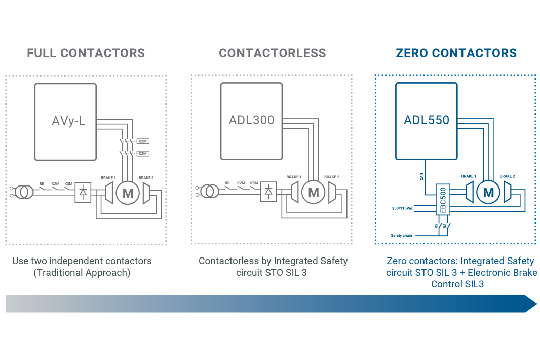

FULL SAFETY PACKAGE

Since years WEG aims to increase more and more the level of safety of the inverters, helping the operators to reduce installation and maintenance costs avoiding the use of external components.

The ADL550 series integrates multiple safety features that are requested by the current standards EN 81-20 / EN 81-50.

Unintended Car Movement (UCM)

According to EN81-20 UCM function requires:

- immediate stop of the car in case of movement with open doors

- Continuous self-monitoring of brakes

- Feedbacks

STO (SAFE TORQUE OFF) SIL 3

- Contactorless by Integrated Safety Circuit STO SIL 3

SBT (SAFE BRAKE TEST)

- Diagnostic function

- Brake holding torque test

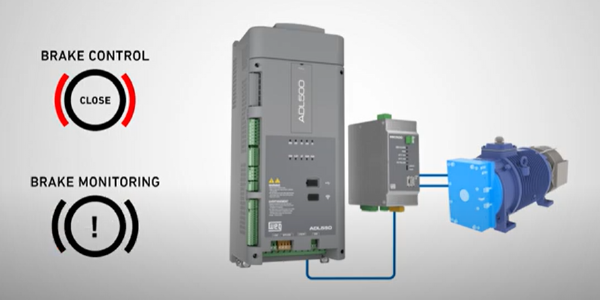

EBC500 (ELECTRONIC SAFE BRAKE CONTROL SIL 3)

- No more expensive and noisy brakes power contactors

- Extended Reliability and Lifetime

EBC500

The integration of the ADL550 with the EBC500 accessory enhances the contactorless concept by further reducing the need for contactors and minimizing complexity within the elevator control cabinet.

The EBC500 module is an advanced electronic device designed for controlling elevator motor brakes, as well as monitoring and adjusting the voltage and current supplied to the brakes. Its primary objective is to streamline the elevator brake control system by eliminating rectifiers and contactors, all while ensuring maximum safety, improving system efficiency, and reducing maintenance requirements.

As a safety-critical component, the EBC500 complies with the European Elevator Standard EN 81-20/50 and is certified as Safe Brake Control SIL 3.