On the northern coast of Rio de Janeiro State, the Polvo-A platform and the FPSO (Floating, Production, Storage and Offloading) Bravo, both from PetroRio, made a tieback, forming a cluster for the extraction and storage of thousands of barrels of oil per day.

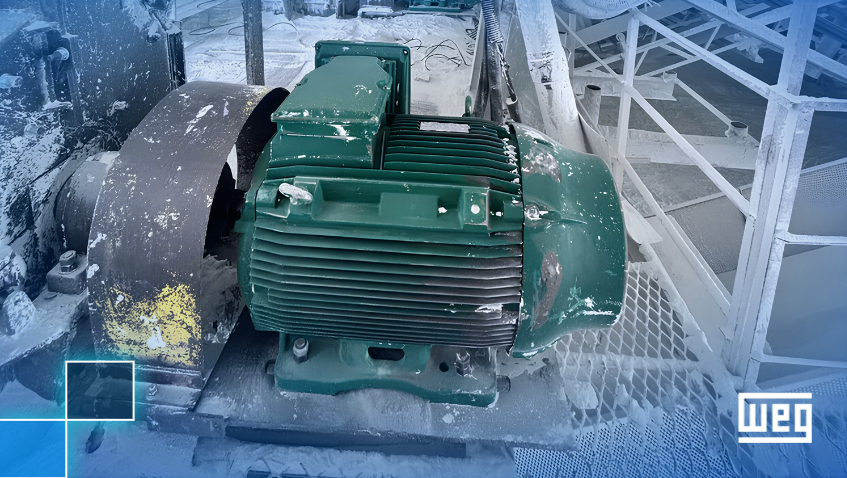

PetroRio purchased four WEG motors at the end of 2021, maintaining the interchangeability with the existing facilities on board. The objective is to increase operational efficiency, expanding production flow and ensuring energy efficiency in the operation.

This supply was produced and delivered in record time due to the customer's urgency, being part of the offshore operation of the largest independent oil and gas company in Brazil. It is another important step towards the nationalization of the equipment supplied to the Oil and Gas segment in the national market.

Savings and sustainability on high seas

Altogether, four motors were delivered to hazardous areas: three 1300HP 4160 V motors installed to drive the transfer of oil and gas from the Polvo-A platform, and one 500HP 460 V motor used in a gas compression skid at the FPSO Bravo, which previously used diesel oil to generate electricity. This system reduced diesel consumption by 60,000 liters a day, which is equivalent to filling the tank of 1,100 cars. In addition, there was a positive environmental impact, with the reduction in the monthly emission of CO2 (carbon dioxide) corresponding to the planting of 30 thousand trees.

PetroRio, specialized in the efficient management of reservoirs and the redevelopment of mature fields, has been renewing equipment and making its processes more efficient and safer, contributing to the extension of the useful life of offshore fields. WEG's expertise and application engineering know-how for the Oil and Gas segment guarantee flexibility in service and competitive lead time, with quality and safety equipment.