TGM G3 Full planetary gearbox set and WEG electric motor provide excellent results to the customer.

The equipment supplied by WEG, responsible for driving the 94” drying mill at Vale do Paraná sugar mill, a plant in the interior of São Paulo that belongs to the Pantaleon Group, reduced the final bagasse moisture from 54% to 47%, as well as obtaining important extraction gains. Already in the first year of operation, the plant's process and revenue results are notorious.

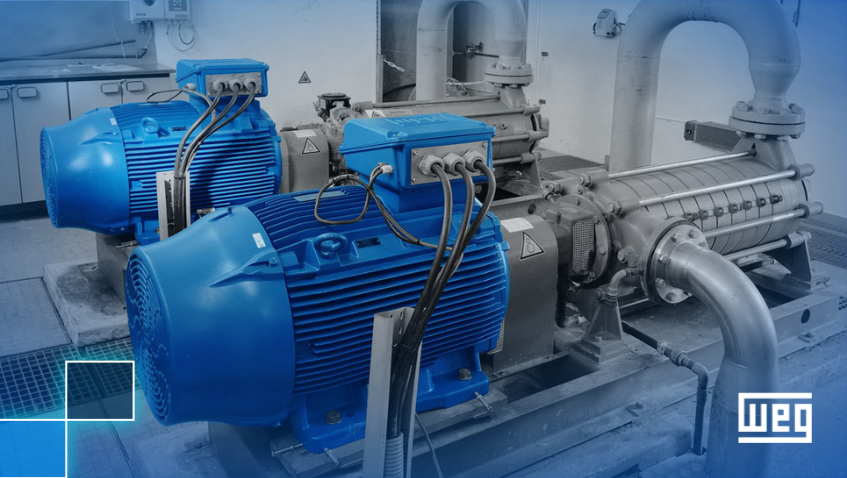

The planetary gearbox G3 Full TGM and the motor W60 line, 2500 HP, 4160 V, 8 poles supplied by WEG started to operate this harvest to activate the drying mill and allow it to work with greater efficiency, better humidity and extraction control, and even increased milling (diffuser). The experience of TGM, WEG Group company, as one of the largest manufacturers of sugar mill gearboxes in the world and the integration with WEG enabled one of the best drive configurations ever seen on the market.

The equipment technical specification favored important results in the plant operation, and its selection was made according to the strategy of reducing maintenance over time, better energy balance, increasing the plant overall efficiency and, obviously, better return on investment. In addition, the installation of a solution with high operational security made all the difference in the WEG equipment selection.

“The installation of the new system has considerably corrected the problems that we had with humidity control and exceeded 98% of extraction, in addition to provide a very stable and simple operation, resulting in an excellent reduction of maintenance in our unit, reducing the investment time”, explained Vanderlei Florencio, industrial maintenance coordinator at the sugar mill where WEG equipment was installed.