Upgrading the process in order to reduce the electric energy consumption is the solution that many companies have sought in WEG efficient solutions. As proof of the effectiveness of its devices, the compressor room of Manufacturing Plant I, in the city of Jaraguá do Sul (Brazil), received a project for compressed air management, especially aiming at saving energy and increasing the plant efficiency.

The compressed air, a result of the compression of the ambient air, is an irreplaceable form of energy in various applications. Nowadays, billions of tons of air are compressed a year around the world, generating a huge power consumption. In the industry, the air compression system is responsible for a high percentage of the energy expenses, and WEG developed a specific project in one of its plants in order to optimize such consumption, creating a control system that combines high-efficiency motors, frequency inverters, dryers and compressors.

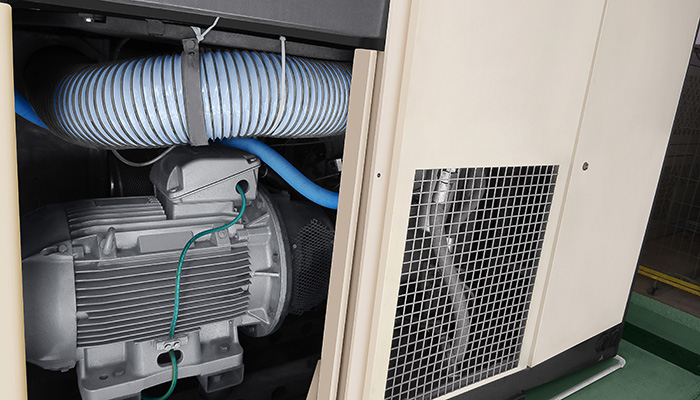

Implanted in March 2016, the structure consists in the automation of the operation of four air compressors driven by high-efficiency electric motors, such as the W22 Magnet IR4 Super Premium, in addition to other motors of the W22 Premium line, always together with WEG frequency inverters of the CFW11 line used for motor start and speed control.

Thanks to such combination, the compressor speed variation occurs according to the compressed air pressure, while the cooling fan speed varies according to the oil temperature.

The compressor room includes a cooling tower, responsible for cooling the driers, which may automatically start or stop consistent with the compressed air flow and humidity conditions. Also in the tower, the electrical panel and the motors of the pumps and exhaust fan were replaced, enabling the speed variation of all electric motors according to the actual cooling requirements.

All the devices were connected to a new control panel, which simplifies the integration and inspection of the automation systems during the operation, such as the state of the motors and inverter, energy consumption, among other data. They are all managed by a software application specially developed by WEG for the operating interface (HMI) with the possibility of connection via network, allowing remote access. The automation was implemented with three-pole contactors of the CWM line, RFW rotary switch-disconnectors, push buttons and pilot lights of the CSW line, a PLC300 programmable logic controller, in addition to communication modules and operating interfaces of the MT series, essential for the success of the process. It is important to point out that the whole project complies with the Brazilian NR10 and NR12 regulatory standards, which determine the safety in installations and services in electricity, also ensured by the use of products of the Safety line.

With an increase in the compressed air generation efficiency and economy of 15% of electric energy – 300 MWh/year, the operation proves its success. For Engineer Maico Jeremias da Silva, developer of the project, the advantages are even bigger, as the implanted solution provides:

• a longer lifespan for the windings and mechanical elements due to the reduced speed, temperature and vibration;

• a longer useful life of the lubricant oil due to the lower temperature;

• lower noise levels as a result of the compressor and ventilation lower speed.

WEG large and varied industrial site allows the implantation and testing of the solutions developed for its customer. Energy efficiency, lower maintenance costs, higher productivity and a longer lifespan of the equipment are some of the many benefits obtained with the smart and monitored use of the systems to generate and treat compressed air, an example of success that can be implanted in different segments.