WEG Motion Fleet Management

Supervisión inteligente de su planta

Desarrollado para traer más practicidad y agilidad en la operación, mantenimiento y gestión de plantas industriales, el WEG Motion Fleet Management es la solución ideal para monitorear y aumentar la disponibilidad de la flota de motores industriales. Basado en la tecnología de “computación en la nube”, el seguimiento de los activos puede realizarse en cualquier momento y desde cualquier parte del mundo.

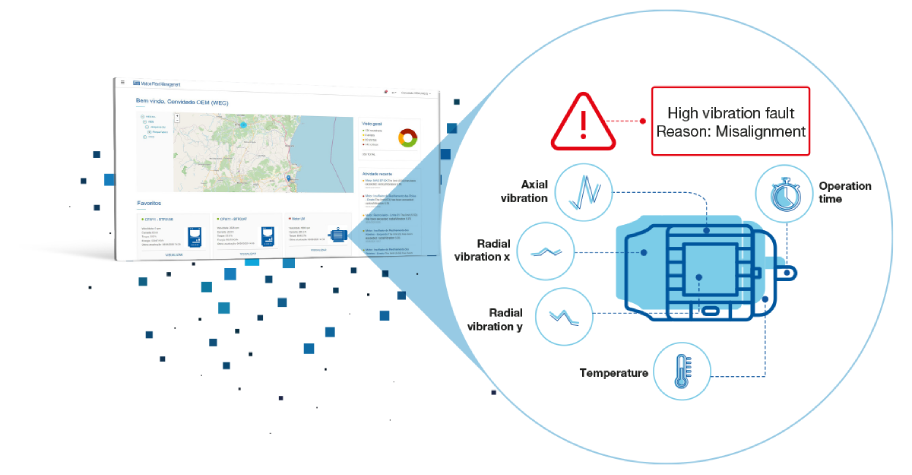

Con WEG Motion Fleet Management es posible conocer el estado de funcionamiento de motores eléctricos, inversores y arrancadores suaves de baja y media tensión, sistemas de arranque por relé inteligente (SRW), reductores, motorreductores, compresores y otros activos, que se aplican en cualquier tipo de industria o instalación. Gracias a la recopilación periódica de datos y al procesamiento avanzado de los mismos, tanto en el borde como en la nube, se generan valiosas percepciones. Así, es posible establecer planes de mantenimiento predictivo, observando el estado operativo de la flota (mantenimiento basado en la condición). Este enfoque reduce el número de paradas no planificadas, optimiza las acciones de reparación y acelera el proceso de toma de decisiones para el equipo de operaciones y mantenimiento. El resultado final es un aumento de la disponibilidad y una reducción del coste total de propiedad (TCO) de la flota de motores.

Conozca nuestros productos

The Importance of Online Asset Monitoring

One of the main causes of lost productivity and profitability in an industry is unplanned production downtime. Most corrective maintenance events could be avoided if machine components and equipment were being monitored continuously (on-line monitoring).

The WEG Motion Fleet Management solution is a high-level tool for operation and maintenance staff to monitor and manage their fleet; o monitor and manage the drive fleet, through hardware for data acquisition, gateways for sending à cloud and software for data visualization and advanced analysis. With WEG Motion Fleet Management is possible to implement a predictive maintenance methodology, well orchestrated, and observing the operational condition of the asset.

Knowing the condition of the assets online contributes significantly to optimizing operational and maintenance resources, such as spare parts management, increased asset availability, and the reduction of (direct and indirect) costs. Additionally, approaches of this type contribute to the increase of asset lifetime, since, in general, a sudden failure results in stress and degradation of the mechanical and electrical elements of the equipment.

Main Features of WMFM Solution

- Asset tree for organizing hierarchy (customer account, units, plants, assets) and measurement points;

- Registration of equipment by type, with construction;

- characteristics to determine failure frequencies and criticality

- Bearing database for diagnostic support;

- Visualization of assets on geographic maps, in an asset tree and multi-level navigation;

- On-demand and periodic reports on equipment, assets and plant operation;

- WEGsense®: technology to detect incipient mechanical failures;

- WEGsync®: technology for multi-sensor synchronous measurement for structural vibration analysis;

- Customization of tolerances for temperature, global multipoint vibration and spectral band to generate alerts and notifications;

- Daily notifications of assets in alert and/or critical state (via e-mail);

- Backup of parameters of AC drives, soft-starters and intelligent relays;

- Module for analyzing vibration signals, in spectral mode and in the time domain, to perform diagnostics;

- Maintenance module with CMMS (computerized maintenance management system) functionalities for creating and managing management of maintenance orders, execution resources and planning;

- WEGscan application for sensor activation, instantaneous measurements and ODS (Operating Deflection Shape) analysis;

- WEG Digital Notify application integrated with the Maintenance Module to speed up the flow of information to the team;

- Specialist modules with Analytics and Artificial Intelligence for autonomous fault diagnosis;

- Exchange modules for integration (via REST API) of data with other platforms and solutions.

Advantages and Benefits of the WMFM Solution

- Monitoring of various types of equipment, assets and plants in a single environment;

- Ecosystem in constant development, both hardware and software;

- Solution integrated with WEGscans, dedicated and robust hardware for the acquisition of application data;

- Data processing at the edge and in the cloud, enabling advanced diagnostics;

- Ready-to-use solution, suitable for a wide variety of equipment and assets, just register the WEGscan in the application and use it;

- Enables maintenance management based on the operational condition of the assets;

- Flexible solution available to service providers;

- Technology to enable the reduction of the plant's operational cost (TCO, Total Cost of Ownership);

- Multilanguage solution and available globally.

Structure

WEG Motion Fleet Management is a modular solution, with a flexible, layer-based structure that adapts to customers' needs. Assets.

Assets

WEG Motion Fleet Management allows on-line monitoring of low and medium voltage motors and drives, as well as gearboxes, gearmotors, compressors, pumps and fans/exhausters.

Scan

WEG Scans and Gateways are hardware responsible for data collection and connectivity of assets to the WEG cloud server, which hosts the WEG Motion Fleet Management application. To monitor the motors, the WEG Motor Scan and Gateway Cassia X1000 is applied, the data upload can be via gateway or smartphone. As for the low or medium voltage drives, the data upload is performed by the WEG Drive Scan.

Management Layer

The Management layer of the WEG Motion Fleet Management application receives data from the WEG Scans and allows the exploration of the functionalities present in the solution. Remember that the solution is constantly improving and new features will be frequently incorporated into the solution. Additionally, users can complement their experience with the Specialist and Exchange modules. They can access the system from anywhere via the Internet whenever a subscription plan is available, which is annual.

Users can view information related to the monitored assets, such as:

- Asset operational condition information (normal, alert or critical);

- Operating parameters such as:

- Rotation;

- Temperature;

- Vibration;

- Power;

- Consumption;

- Current;

- Voltage;

- Operation History;

- Failures/Events and interventions;

- Configurable alerts and notifications.

Diagnostics & Integration

With active subscriptions to the WEG Motion Fleet Management layer, users can complement their experience with subscriptions to specific modules such as WEG Specialist and WEG Exchange.

Specialist Module

The Specialist module applies algorithms specially developed by WEG for advanced data analysis, by means of Machine Learning and Artificial Intelligence. These algorithms are applied to the data collected by WEG Scans and thus generate useful information, something essential for efficient fleet management. As is the case of WEG Motor Specialist, which has a sub-module for diagnosing mechanical failure and another for evaluating the engine's energy consumption. Both functionalities were developed by WEG's team of specialists and were validated in the company's laboratories.

These advanced analysis algorithms observe and learn the patterns and operating deviations of the monitored electric motor, generating failure indicators for unbalancing, misalignment, rolling (advanced failure) and external vibration. This type of information is very useful for operation and maintenance staff, as it aids in decision making, speeds up the repair process, and minimizes unscheduled downtime. In order to use the Specialist layer, the respective asset(s) must have an active WEG Motion Fleet Management subscription. Both subscriptions are annual and per asset.

Exchange Module

The Exchange module allows the customer to integrate the information collected and present in WEG Motion Fleet Management in its own management system and/or platforms. Through periodic and automatic data requests of the Web Service REST type, the WEG Motion Fleet Management data is sent to the customer's system or a third party system. To use the Exchange layer, the respective asset(s) must have an active Management layer subscription. Exchange subscriptions are annual and per data packet.

WEG Drive Scan

Developed to connect low voltage inverters to WEG Motion Fleet Management, the WEG Drive Scan line periodically collects and transmits important data from the inverters, allowing monitoring to be done at any time and from anywhere in the world.

Access the catalog and learn more.

WEG Motor Scan® + Specialist

WEG Motor Scan® is the monitoring solution for total control of the manufacturing plant, ensuring, via predictive analysis, the level of excellence in the performance of electric motors and other equipment. With it, data is extracted and sent to the cloud, allowing preventive actions and avoiding risks of production stoppage. The industry will never be the same again!

Access the catalog and know more.

KNOW MOREAre you in doubt?

Check out the most frequently asked questions.

Using the positioning instructions shown in the figure on the mobile app itself, bring the top of the sensor (region with product markings) near the smartphone NFC region.

The user must be a plant administrator to register new sensors and manage them through the mobile app. Request the administrator access to the desired plant or create a new plant to register the asset and sensor.

Using the mobile app, it is possible to view the WEG Motor Scan sensors within the range of the smartphone or tablet Bluetooth on a list of nearby sensors. If it is a new, unconfigured or reset sensor, it will not appear on the nearby sensors screen. This sensor must be configured again by selecting the option "New Device" – "Select" – "Configure" in order to appear in the list of nearby sensors.

No. Through the App you will view the data of the last vibration and temperature readings. Using the “Advanced Measurements” button, in addition to the temperature and global 3-axis vibration, the user can view the vibration and speed spectrums.

Know more about WEG news on Industry 4.0

A new way to combine people, business, technology and efficiency

Access our sandbox for free and see how digital transformation is impacting industrial markets and revolutionizing the way we produce.

KNOW MOREDid you like WEG Digital Solutions and want to know more?

Choose one of the options below:

Do you want to receive our news?

Contact us and ask your questions.