The Hübner Group is an important supplier to the automotive industry, with expertise in foundry, machining and assembly, which frequently monitors industrial processes to prevent environmental impacts and improve the use of natural resources.

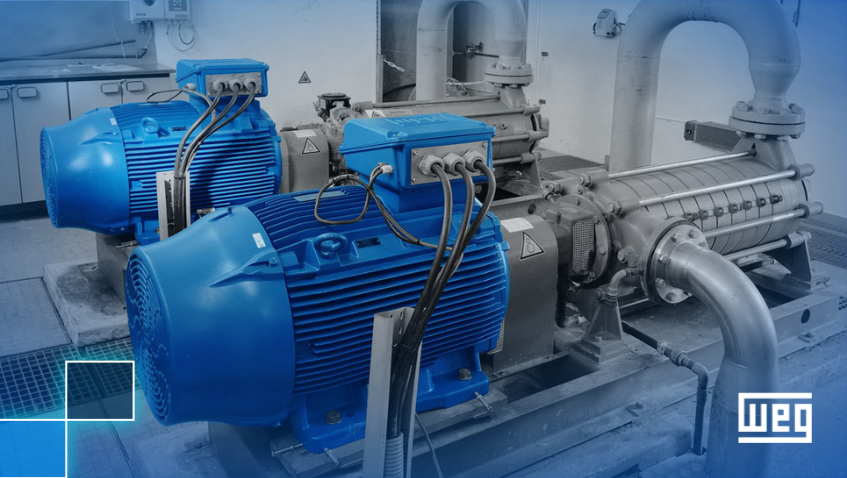

For better results, the company sought WEG to implement an energy efficiency project. The IR1 efficiency motor installed on the cooling tower fan was replaced with a W22 IR3 Premium motor – which meets the new level of minimum performance for low voltage electric motors in Brazil, in force since August 30, 2019 – operating together with a CFW 700 frequency inverter.

This application uses the exclusive WEG software, not requiring controllers and PLCs and performing direct control by means of the frequency inverter, to reduce the consumption of electrical energy in the Closed Circuit Cooling Tower 26 (Evaporative Cooler), located in HCSA 03 - Industrial Tower. In addition, controlling the speed variation can reduce water evaporation and consequently the consumption of refilling water.

The Cooling Tower is a device for cooling water used in industrial processes. The variation in the conditions that surround its operation allows the system automation, very accessible to any application and with great reduction of operating costs. As a result, the company achieved a 67.3 % reduction in electricity consumption, which corresponds to 18,109.70 kWh/year.

The Hübner Group's commitment to carrying out energy efficiency projects represents the company's values, which focus on continuous improvement through a high performance culture.

WEG, recognized for its Energy Efficiency solutions for various industrial applications, offers the market several combinations of high efficiency products to reduce energy consumption and improve industrial processes worldwide.