Extruder

Lower costs and higher efficiency

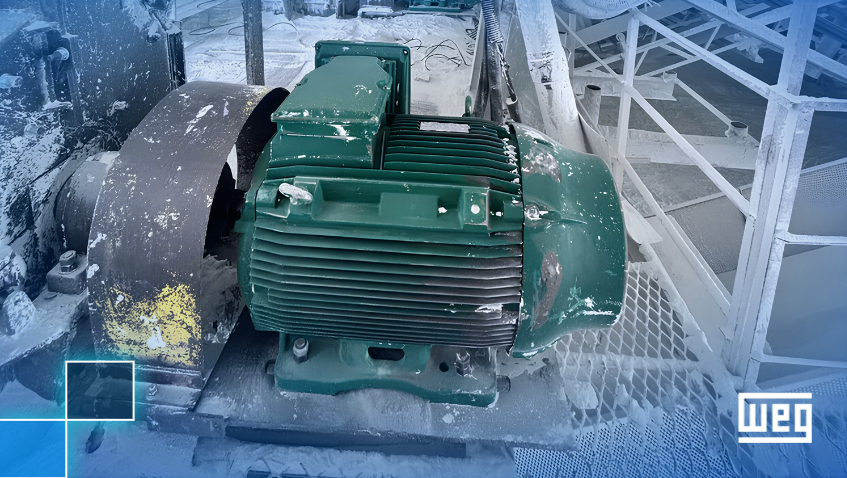

Plastic extruders are machines for forming plastic polymers into specific shapes according to the die used. The material is moved by means of a thread driven by an electric motor coupled to a gearbox, since the speed for plastic forming is very low, demanding a high torque.

As many machines still in operation are old, the use of direct current motors for this application is very common, since they were an efficient way to control speed in the past.

WEG solution to save electric energy consists of replacing direct current motors by high-efficiency permanent-magnet motors. W22 Wmagnet driven by CFW11 variable speed drives. In addition to energy savings, this set provides lower maintenance costs, since frequent maintenance procedures, such as electric brush and air filter replacement, are unnecessary

Benefits

- Electric energy savings of up to 30%.

- Easy implantation with few impacts on the production system and extruder.

- Lower maintenance costs.

- Greater uniformity in the extrusion process.

- Better quality of the extruded product.

- Extendable to other direct current driving systems.