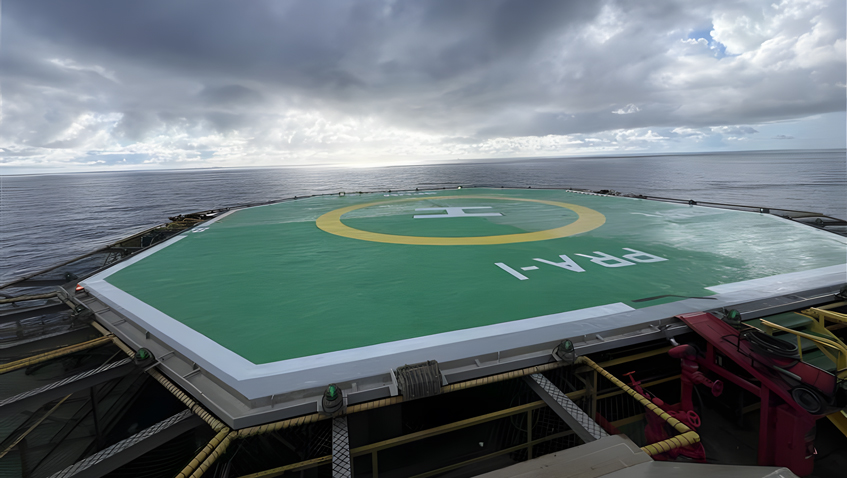

WEG, in partnership with GranServices, INSUP-RO Petrobras, and in collaboration with the Petrobras Research and Innovation Center (CENPES), successfully completed the application of an innovative, high-resistance solution on the PRA-1 helipad. The WRAPX® HBD 332 coating, specially developed by WEG, was selected to withstand the challenges of corrosion and frequent impacts in harsh environments, ensuring the helipad’s seal and durability.

WRAPX® HBD 332 is a flexible epoxy coating that stands out due to its exceptional mechanical properties and its application in high thickness in a single coat, simplifying the operation and reducing application time. With 22% elongation flexibility, the coating accommodates expansion and contraction movements on metal surfaces, preventing cracks and ensuring greater structural integrity. This technical advantage allows the coating to withstand aggressive conditions, such as those found on offshore platforms, chemical plants, and in this case, a helipad.

During the execution of the project, the helipad’s surface was prepared using ultra-high-pressure water blasting, and during the painting process, WRAPX® HBD 332 was applied in a uniform 5mm layer, reinforced with polypropylene mesh at the plate joints to ensure greater flexibility and maximum mechanical strength. The finalization included the application of an anti-slip coating, resulting in a watertight floor that facilitates liquid drainage, increasing not only the helipad’s durability but also operational safety.

In addition to its mechanical properties and impact resistance, WRAPX® HBD 332 offers significant operational advantages:

- Longer maintenance intervals: The durability provided by WRAPX® HBD 332 results in greater operational availability of assets, with less downtime.

- Optimization of production processes and reduction of operational costs: The quick release of equipment after application, due to its high-thickness single-coat application and low sensitivity to adverse conditions such as humidity, enables agile responses to operational and maintenance needs.

The WRAPX® line utilizes high-performance coatings that extend asset integrity. According to the Liquid Paint Development Manager, Eder Dirceu Dela Justina: “The choice of WRAPX® HBD 332 for this application reinforces our commitment to solutions that combine innovation and efficiency, ensuring asset protection and longevity in harsh conditions, especially in the offshore environment.”

Combining performance, strength, and sustainability, WEG consolidates its position as the ideal technical partner for the industrial sector. Learn more about WEG solutions and our dedication to providing cutting-edge technology for challenging environments.