Alimentos y Bebidas

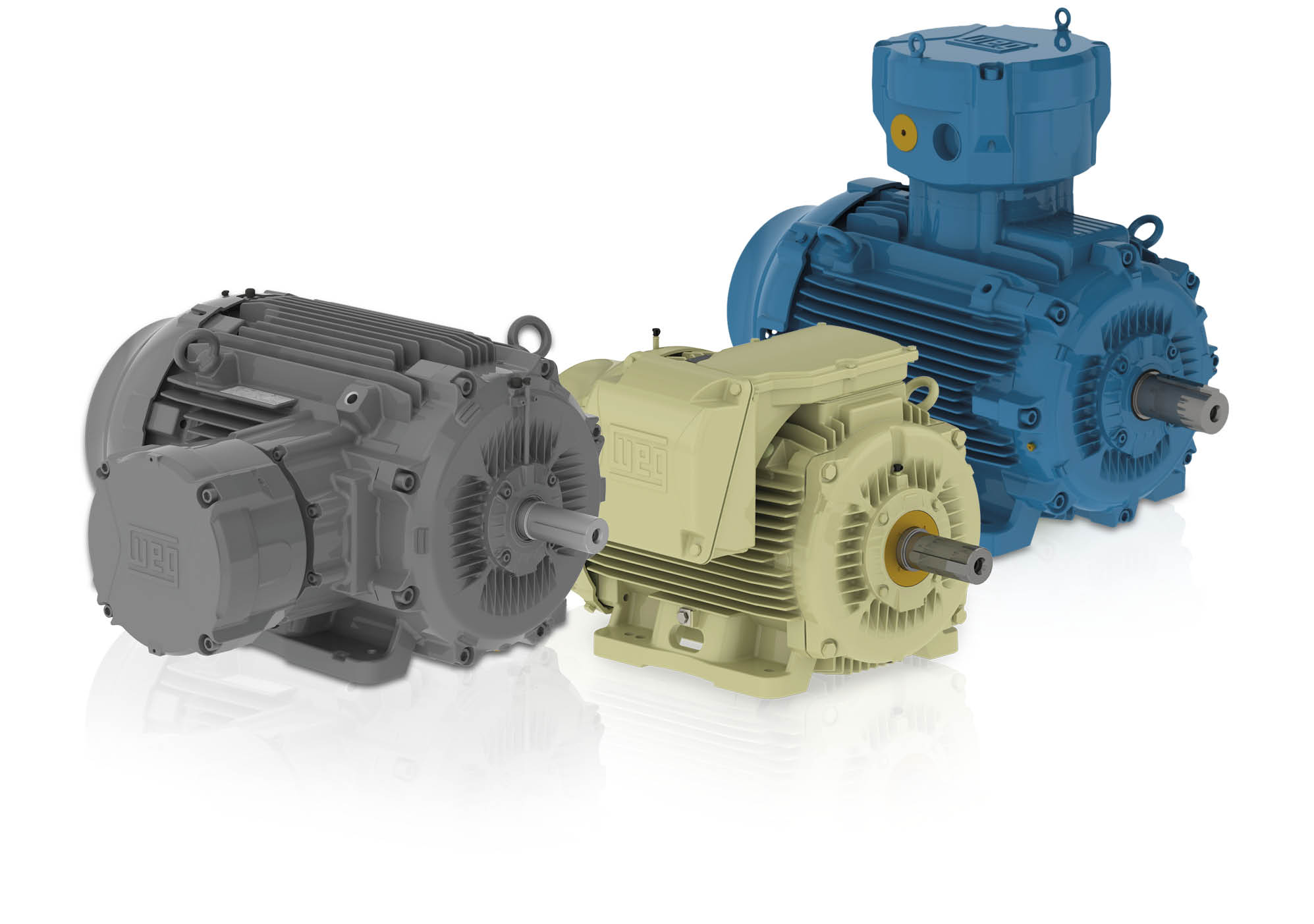

Motores y Reductores

Eficiencia y Confiabilidad para la industria de Alimentos y Bebidas

La fabricación de los motores eléctricos WEG empezó con la combinación de habilidades de un electricista, un administrador y un mecánico, que resultó en la producción del primer motor eléctrico WEG. Desde entonces, es eso lo que nos orienta a producir máquinas más eficientes, proyectadas con las tecnologías más avanzadas. Todo eso porque, independiente del segmento de mercado, WEG mantiene iniciativas dedicadas de investigación e innovación para la producción de motores eléctricos de alta eficiencia, que garanticen la confiabilidad de la producción para su industria.

WEG offers various solutions with electric motors and gearboxes, such as permanent magnet motors, antimicrobiotic and corrosion resistant painting, and new technologies for Industry 4.0, such as WEG Motor Scan. These are products specifically designed for any application in the Food and Beverage Industry.

Ventilation, Exhaust and Pumping Systems

These systems incorporate several WEG solutions, such as motors for ventilation in poultry farms and for silos. Additionaly, WEG offers the WECM (WEG Electric Commutated Motor), which is designed for freezing tunnels, condensers and evaporators; the W12 which can be used with gearboxes, pumps and fans, while the W22 line offers all of its versatility and efficiency. Developed for large exhaust and pumping systems, the W60 motors offer high levels of energy efficiency, ideal for high speed applications.

Washdown Application Environments

Applications requiring continuous washdown process (handling animal protein, such as: pork, beef, lamb and poultry) demand safe equipment. WEG offers solutions like the Encapsulated Washdown Motors Hydroduty and Picker Plus, and General Purpose Washdown Motors Hydrowash, Shark and W22 Wash, which features NobaC®, exclusive WEG paiting with antimicrobial properties.

Preparation and Processing

WEG designs equipment intended for the preparation and processing of industrialized food. Included in this portfolio are the dedicated electric motors and gearboxes.

Air Compressors and Cooling Systems

Applications such as ammonia compressors, oil extractors, centrifugal machines, stirrers and flammable gas environments demand dedicated and realiable products.

WEG also offer the W60 line, with a compact design and optimized air flow, dedicated to pumps, fans, compressors, presses, calenders and emulsifying machines. The highlight is the W22 Cooling Tower motor line, used in cooling towers.

Material Handling

Gearmotors such as the WG20, Magmax and GSA, and the new W12, are suitable for applications like rolling machines, stirrers, winches, elevators, chippers and conveyor belts. Some applications may receive special antimicrobial painting, resistant to corrosion, which is important for the Food and Beverage industry.

Hazardous Locations

These electric motors meet the needs of hazardous locations, as they are manufactured according to current industrial standards, both NEMA and IEC. The products are certified by the main product certification bodies in the world, in addition to having high safety levels, essential for Zones 1 and 2. With a robust construction, they are the most modern drives for hazardous locations machines containing gas or steam.

Know more about our solutions

Download our brochure and know more about our solutions for Food and Beverage.

Download