Automation Systems

With thirty years of experience as system integrator, developing software applications for PLCs and supervisory applications, WEG counts on a solid team of engineers and specialists in automation for Sugar & Alcohol plants, from the instrumentation project to the development of supervision and control systems, with a high level of integration between the different levels of process control and automation.

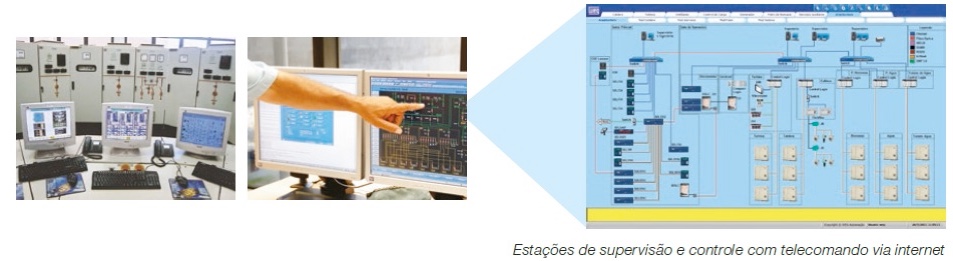

Remote Operations and Maintenance

Using resources of remote connection via internet, in a safe and quick way, maintenance and operations of the plant are carried out at with reduced costs.

Supervision and Control of Steam and Energy Production (Turbogenerator and Boiler)

WEG automation systems for the electrical sector covers the whole cycle for energy generation: transportation control and biomass preparation, automatic boiler control, as well as automatic operation of the turbine and generator. Currently, hundreds of projects in the energy sector are in operation with WEG control systems.

- Full automation of biomass and gas boilers

- Automatic control of energy import and export

- Full monitoring of steam turbines

- Automatic control of gas and diesel oil burners

- Integration of the water treatment system and biomass yard

- Integration of the medium voltage cubicles with high performance networks

- Process variable control by means of PID algorithms and advanced control

Supervision and Control of the Sugarcane Mill and Diffuser

- Speed synchronism between rolls

- Load distribution control

- Supervision of the auxiliary systems

- Cascade control for the level of the three-roll mills

- Local operation and supervision via HMI

- Automatic control for imbibition

- Production totalizers and indicators

Process Supervision and Control

Full automation solution for the whole process of Sugar & Ethanol production, from the instrumentation project to the development of the supervision and control system. Through specialists in the sector, the solution provides high integration between the different levels of process control and automation.

The automation focused on the needs of each customer allows the creation of integrated and customized systems, simplifying the operation and maintenance of the plant.

See more cases

Costa Bioenergia factory, in Umuarama, Parana.

Watch the videoLearn more about WEG news on Sugar and Ethanol.

Are you interested in this solution? Choose one of the options below to find the product you need

Contact us and we will be glad to answer your questions