Through the company's strategic direction for its business model, WEG has, in all its business units, more efficient solutions and products with less environmental impact, such as renewable energy (solar and wind power), electric mobility and energy efficiency. WEG develops products considering strict risk criteria related to health and safety. In the development phase, analyzes such as Quality Function Deployment (QFD) and Risk Assessment are applied.

Below are some highlights, considering the variety of products and solutions that the company provides to the market through its different business units.

Energy and Industrial Efficiency

W51 HD Motor (High Density)

Efficient and compact solution thar delivers high performance with reduced size and weight in comparison to the previous line (up to 25% higher power density – kW/kg) and its competitors. Therefore, it makes rational use of raw materials in the manufacture of motors and reduces the potential effects of their transformation, cutting down GHG emissions by about 15% in comparison to the previous line.

VSD for Motors

High-tech VSD for driving and controlling three-phase induction and permanent magnet motors. Thanks to its technology, this VSD model provides energy savings, safety, increased productivity and quality in the process network in which it is implemented. The CFW900, together with permanent magnet motors, offers the highest energy efficiency solution on the market. The new HMI with Bluetooth® connectivity is ideal for panel builders and repair shops, enabling programming, monitoring, parameter backup and other functionalities via tablets or smartphones.

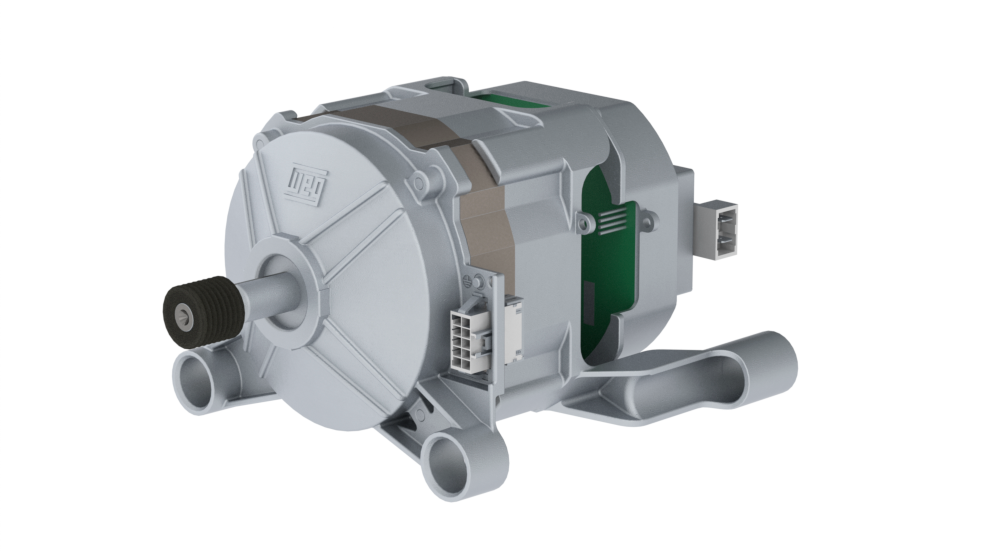

BLDC Motor Line (Brushless DC)

For application in front load washing machines, it delivers a 60% improvement in the performance of the operating cycle and, consequently, a reduction of GHG emissions during the operation phase. This line currently represents 20% of the volume sold by WEG for front load washing machines.

Renewable Energy

Wind Power

In July 2022, WEG announced the release of a new wind turbine platform with 7 MW power and 172 meters of blade rotor diameter. This wind turbine will become the largest machine in operation in the Brazilian market. More powerful and efficient, the new model brings greater generation to wind projects.

Solar Power

WEG established itself as one of the main suppliers of products and solutions for solar plants in Brazil, bringing efficiency that drives sustainability in cities, industries, agribusiness and homes across the country. WEG has a vast portfolio of products for all the stages of photovoltaic solar generation projects, with solutions for the energy conversion and internal distribution system, from the plant to the point of connection to the electrical system through high voltage substations.

Hydroelectric Generation

WEG was selected to supply the generators for São Roque Hydroelectric Power Plant, located in the city of Vargem-SC. The generators are one of the most important parts of the enterprise for São Roque Hydroelectric Power Plant. With 285 tons each and approximately eight meters in diameter, this equipment is among the largest electric hydrogenerators ever produced by WEG.

São Roque Hydroelectric Power Plant has an installed capacity of 142 MW, which, on average, is enough to supply a city with approximately 170,000 inhabitants. The generators started commercial operation in July 2022.

Commercial and Industrial Energy Storage

Energy storage systems are used in commercial or industrial facilities, being the complete solution for storage and management of electrical energy. They can be configured to perform various functions in smart systems for generation, transmission and distribution of electric energy. The system is composed of an energy control and management solution, and it is mainly recommended for applications in systems installed behind the meter in industries, stores, shopping malls, residential condominiums and electric mobility infrastructure.

Transformers for Renewable Energy

The reliability of the transformers developed for solar plants aims at guaranteeing the supply of energy, allowing access to electricity through renewable energy generation sources. In the line of transformers for wind farms, WEG developed an extremely compact electrical and mechanical transformer design. Additionally, due to the installation layout, in which the source and the transforming unit are very close to each other, the system produces smaller losses and greater energy efficiency.

Electrical Mobility

Integrated solutions for electric vehicles

WEG continually develops innovative technologies to create electric traction systems, as well as all the electrical infrastructure necessary for the operation of electric vehicles. WEG electric traction systems can drive various road, rail and navigation vehicles, such as urban trucks and buses, vans, forklifts, trains, monorails, support vessels and tugboats.

Digital Solutions

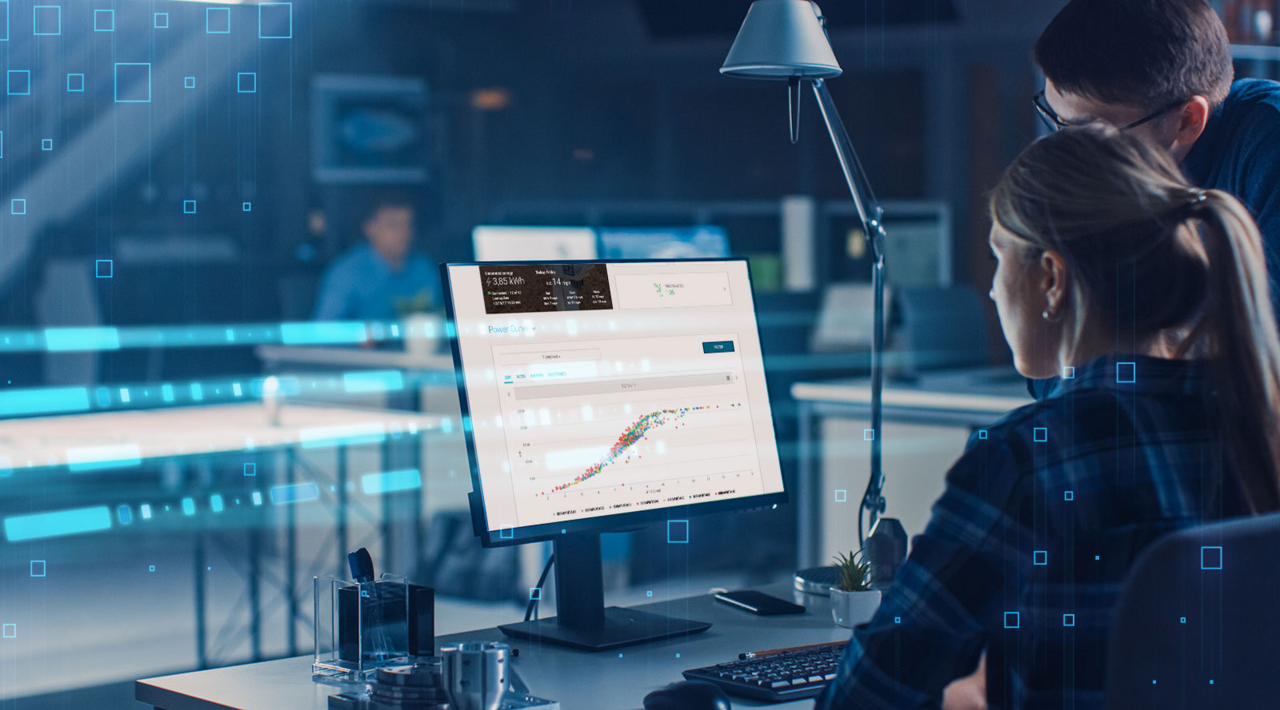

Smart and sustainable systems

Smart systems are able to integrate different devices and machines, as well as installations and processes, promoting efficiency in decision-making and increasing operational efficiency. Smarter solutions and systems also promote more efficient use of energy resources helping reduce the carbon footprint of operations at all levels.

Automation Systems

WEG supplies completely integrated control systems that guarantee high performance of industrial processes, easy operation and productivity gains by means of state-of-the-art technology. The success of the integration of this system is in the synergy of WEG products, where motors, drives, generators, electric panels and software applications are integrated, providing the ideal solution for each requirement. The control of industrial processes requires automation systems with high reliability and uptime levels, in addition to easy asset management by the maintenance teams, extending the equipment service life and streamlining the use of resources.

WEG Transformer Fleet Management and WEG Power Transformer Specialist

WEG Transformer Fleet Management es la solución ideal para monitorear online y supervisar la flota de transformadores a aceite o del tipo seco, posibilitando que los clientes maximicen la eficiencia de sus operaciones, en apoyo a la gestión optimizada de plantas industriales, de generación de energías renovables y de infraestructura. Por otro lado, la solución WEG Power Transformer Specialist es una solución digital aplicada en el monitoreo y en la gestión de transformadores de potencia que, integrada a la plataforma WEG Transformer Fleet Management, centraliza las señales de una serie de sensores instalados en el equipo.

WEG Motion Fleet Management

Desarrollado para llevar más practicidad y agilidad a la operación, en el mantenimiento y en la gestión de plantas industriales, el WEG Motion Fleet Management es la solución ideal para monitorear y elevar la disponibilidad de la flota de accionamiento industrial. Basado en tecnología “cloud computing”, el monitoreo de los activos puede ser seguido en cualquier momento y desde cualquier parte del mundo. Con el Motion Fleet Management es posible conocer el estado operacional de motores y drives (convertidores y arrancadores suaves) de baja y media tensión, reductores, motorreductores, compresores, entre otros activos que estén aplicados en cualquier tipo de industria o instalación

Tecnología Ultra Low Bake (ULB) para Pinturas

La tecnología Ultra Low Bake (ULB) consiste en reducir el tiempo de cura o la temperatura de cura de las pinturas en polvo. Asociado a esa reducción de tiempo o temperatura (que puede llegar a 35% de reducción), reduciendo la cantidad de gas que es utilizada en los hornos de cura de sus clientes y aliados, así como reduciendo las emisiones de GEE.

Los aliados de WEG que poseen esa tecnología en su línea de producción, además de la reducción del impacto ambiental, tienen aumento significativo de productividad y en su competitividad. WEG cuanta con cuarenta productos desarrollados con esa finalidad.

Eficiencia material y evaluación ambiental del producto

WEG adopta, en su cadena de valor, iniciativas que están alineadas a los principios de la economía circular, a través de prácticas como reinserción de residuos de los procesos como materias primas, como por ejemplo chatarra de acero de la estampería, para fabricación de piezas fundidas, adopción de programas de recuperación de materiales en el fin del ciclo de vida de productos, a través de la logística reversa y de planes de cambio.

La aplicación de esos conceptos y prácticas permitieron a WEG alcanzar un índice de eficiencia material de cerca de 85%. WEG también está en constante mejora y evolución de la eficiencia energética de sus productos y de soluciones de retrofit para la extensión de la vida útil de algunas líneas de productos. Equipos cualificados actúan tanto en los procesos de desarrollo de nuevos productos y en la concepción de nuevas líneas, como en la implantación de procesos industriales más eficientes.

WEG aplica el ACV (Análisis de Ciclo de Vida), generando los EPDs (Environmental Product Declarations) conforme las demandas de los clientes, con el objetivo, en los próximos años, de ampliar la aplicación de esas herramientas.