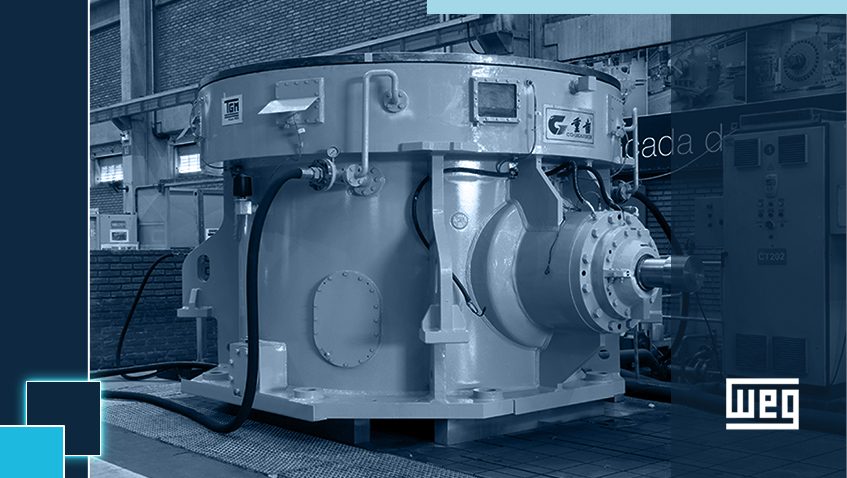

WEG, specialized in rotating machines for electrical and mechanical drives, received a 35 MW steam turbine for repair services. The turbine was completely disassembled, revised, reassembled according to the original design, painted, and dispatched in a record time of five days.

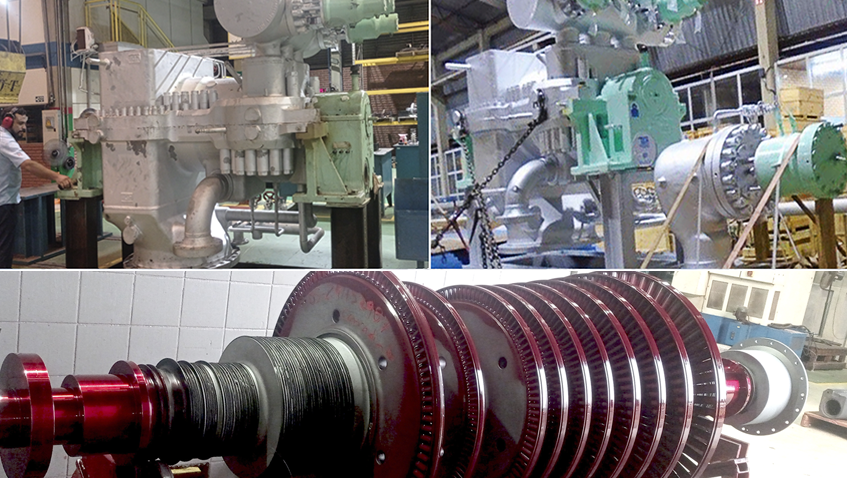

The following services were performed: frame and valve block machining, LP and LM tests, rotor strip replacement and balancing, bearing alignment, clearance measurement, replacement of spare parts, revision and testing of steam control and quick-closing valves.

After intensive revision services in our facilities to restore the turbine's operational conditions, the field team worked quickly to successfully put it back into operation, restoring its maximum power of 35 MW in order to generate power to the plant. This achievement led to the customer's satisfaction and recognition for the services provided by WEG.