Circular and efficient operations

The circular economy seeks to maximize the value of resources while minimizing waste and environmental impacts. In this model, products are designed to be durable, repairable and recyclable, encouraging the reuse and recycling of materials. Instead of following the traditional linear model of production and consumption, in which products are manufactured, used and discarded, the circular economy promotes the idea of a continuous cycle, where materials are kept in use for as long as possible.

This approach not only contributes to the conservation of natural resources but also stimulates innovation, job creation and sustainable economic growth, making it essential to address today's global challenges such as climate change and resource scarcity.

Consolidating WEG's commitment, we have ISO 14,001 certifications demonstrating environmental management in the company's operations.

Programs & Practices

Residues and energy

Solid residues

WEG operations have a selective waste collection system. In this way, residues are separated and sent to recyclers of each material, enabling their appreciation and the reintroduction of such materials in different production cycles. It is important to emphasize that part of the waste generated in the operations is recycled by WEG itself, returning to the process and forming part of its products. All waste is sent to environmentally responsible companies, selected and developed by WEG's environmental management team.

Energy

WEG has had an Energy Efficiency Policy since 2012, showing its commitment to the management of this input. This policy is deployed into actions to monitor and reduce energy consumption, which contributes to improving the environment. WEG intends to increasingly make its energy sources cleaner, renewable and sustainable.

Water, effluents and water resources

WEG monitors the water consumption of its operations and has several operational controls that ensure efficient management of this resource, thus avoiding waste and promoting conscious consumption. All effluents generated in operations are properly treated and periodically monitored in order to ensure compliance with legislation and minimize impacts on different stakeholders.

Part of the effluents treated in the operations are reused in the internal processes, where some effluent treatment plants enable the reuse of up to 100% of the treated effluent. We have adopted initiatives focused on reducing water consumption and effluent generation by controlling leaks, monitoring consumption and counting on the support of programs that engage all employees in this objective, such as KaizenWEG and WEG Manufacturing System.

Investments and expenses in the environment

Environmental investments fall into three categories:

- Environmental control: related to treatment and disposal of residues, treatment of atmospheric and liquid emissions, environmental liability insurances, depreciation of devices and expenses with materials and maintenance.

- Equipment: related to the purchase of equipment for environmental control.

- Management: related to the remuneration of training staff who act in environmental management, research and development, and certification of environmental management systems.

Sustainable packaging and biodiversity preservation

We have a packaging factory, RF Reflorestadora, in Brazil. This unit produces all the wooden packaging used in our various product lines. To that end, we have our own reforestation areas that guarantee the continuous supply of wood and the preservation of this natural resource and areas of natural forests, legal reserves and permanent preservation areas that help in the preservation of the local biodiversity.

The areas comply with all legislation and legal requirements, including an area of conservation of native forests much larger than the minimum established for the legal reserve.

Furthermore, WEG promotes and supports conscious reforestation and nature conservation initiatives and invests in the afforestation of its industrial parks.

KaizenWEG

KaizenWEG was created in 2016 and is the heart of WEG's continuous improvement management system, the WMS, where all employees are encouraged to promote improvements in their work environment or in any other areas of the company, identifying waste, analyzing causes, and participating in multidisciplinary teams for problem solving.

As one of the pillars of the Company's Participative Management, since its creation more than 300,000 improvements have been implemented, bringing more safety, quality, and productivity, as well as making the work environment increasingly efficient and sustainable.

The collective pursuit of operational excellence and sustainability in a scenario of process verticalization makes participative management a key element in boosting WEG’s results.

Watch the video of the launch of the new KaizenWEG platform:

WMS (WEG Management System)

WEG's continuous improvement management system is WMS, whose main objective is to identify and eliminate losses and waste.

Results are maximized through safety, quality, cost and GHG (greenhouse gas) emission prioritization matrices, which guide the development of projects to optimize or eliminate such waste, contributing to a more efficient and sustainable world.

In addition to the optimization work fronts, multidisciplinary teams act as central points for continuous improvement, bringing innovations and disruptions to our processes.

One of these central points is the Environment and Energy pillar, which aims at and systematizes the reduction of environmental impacts, working to reduce or eliminate the generation of waste and emissions, the consumption of energy resources, chemical cleaning and inputs in general.

WEG Replacement Plan (Available only in Brazil)

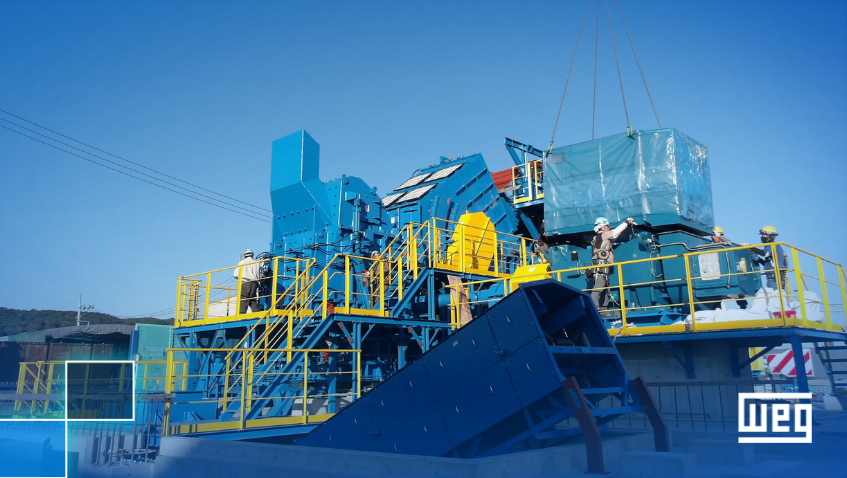

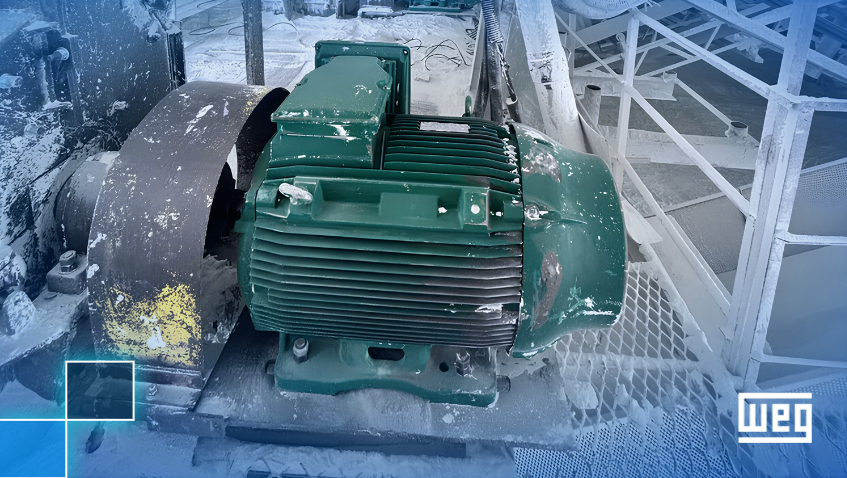

Recycling is a serious subject for WEG, extended up to business. By means of the program for reusing electric motors, the “Exchange Plan”, the company has granted a discount on the purchase of a new motor with performance above the law requirements in exchange for a used one. Besides the financial benefit to the customers, the initiative ensures that the low-efficiency motor is no longer used. Once collected by the company, the motors are dismantled and separated into parts for distribution to accredited and tracked recyclers.

Benefits

Reduction of electric energy consumption

Reliability of the plant

Reduction of operating costs

Factory Warranty

Standard products - offer complete interchangeability with motors already installed

Item | 2021 | 2022 | 2023 | 2024 |

Products sold that can be reused or recycled* (%) – Weight basis | 68 | 73 | 65 | 70 |

Products that were actually reused or recycled by the company * (%) – Weight basis | 12 | 16 | 14 | 4 |

* It takes into account only the products placed and recalled in the Brazilian market

Investments in Environment

Environmental investments are classified into two categories:

Capital Investments: Refer to the acquisition of environmental control equipment.

Operating Expenses (R$): Refer to waste treatment and disposal, atmospheric and liquid emissions treatment, environmental liability insurance, and equipment depreciation, as well as expenses for materials and maintenance, as well as expenses for the compensation of personnel working in environmental management, research and development, and certification of environmental management systems.

Below is the amount invested in each category:

Item | 2021 | 2022 | 2023 | 2024 |

Capital Investments (R$) | 1,329,000 | 1,788,000 | 1,819,000 | 11,141,393 |

Operating Expenses (R$) | 14,684,000 | 17,753,000 | 23,509,000 | 33,605,910 |

| % of operations covered (%) | 70 | 70 | 70 | 89 |

Enviromental Certification

In 2024, considering the scope of employees, 70,8% of the WEG group was covered by ISO 14001 certification.

Click here to access the certificates

Environmental Audits

WEG has an environmental audit cycle process that covers all of its industrial operations.

In annual environmental audit process, WEG guarantees compliance with environmental legislation in all industrial operations.

Performance Indicators

In 2023, the scope of monitored units was expanded, including the company's business addresses. Thus, 100% of WEG's global addresses are now included in the indicators.

Energy

WEG has had an Energy Efficiency Policy since 2012, in which it shows its commitment to the management of this input. This policy develops actions to monitor and reduce energy consumption, which contributes to improving the environment. WEG intends to increasingly make its energy sources cleaner, renewable and sustainable.

Total energy consumption | Unit | 2021 | 2022 | 2023 | 2024 |

Total non-renewable energy consumption | MWh | 535,599 | 510,110 | 454,702 | 212,113 |

Total renewable energy consumption | MWh | 57,801 | 88,904 | 129,202 | 427,398 |

Total energy consumption (Non-Renewable + Renewable) | MWh | 593,400 | 599,014 | 583,904 | 639,511 |

Coverage data (%) | In relation to employees | 100 | 100 | 100 | 100 |

Renewable energy acquisition

In 2024, WEG ensured that 66.8% of energy consumption would come from renewable sources with guaranteed origin through self-production, purchase of renewable energy certificates (I-REC) and bilateral contracts.

Atmospheric emissions

WEG monitors atmospheric emissions related to volatile organic compounds. Below is the result of emissions related to equipment monitored in recent years.

Item | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 |

Emissions of volatile organic compounds - VOC (t/year) | 93.5 | 135.2 | 114.5 | 139.3 | 191.3 | 241.3 |

coverage rate (%) | 56 | 56 | 56 | 61 | 72 | 61 |

Environmental Violations

One of WEG's top priorities is compliance with the environmental legislation applicable to its operations. In the last 4 years, there were no evidence of significative environmental fines applied to WEG businesses.