Coatings

WEG’s Coating Business Division has been providing industrial and anti-corrosive coatings for over thirty years to manufacturers of machines, equipment and metal structures with experience in the mining sector. Designed to meet the different requirements of ore extraction, processing and transportation, WEG’s specialist durable coatings aim to reduce corrosion and fatigue and cut down on maintenance ensuring higher productivity over time through fewer shutdowns.

Exposure to chemical and corrosive materials, high humidity and abrasive materials in production, processing and handling during ore extraction generate a demand for high-performance coatings.

Excess of dust and humidity

Excess dust in the extraction, crushing, sieving, grinding and handling of ore and cement is inherent, in many situations the extraction occurs in humid environments. This means that the coatings on the machines, equipment, conveyor belts and metal structures must be highly resistant, easy to apply and cost effective.

WEG double-function epoxy line, together with the polyurethane topcoat meet the requirements for these processes and are recommended for construction through to maintenance.

Immersion and direct contact with liquids

During production, the use of separation techniques based on gravity, flotation or leaching exposes equipment to continuous contact with liquids, often in extremely aggressive environments. Pipes and metal frames that are buried or submerged in fresh or salty water also require protective coatings.

WEG’s technologically advanced resins ensure excellent performance as indoor or outdoor coatings for pipes, storage and mixing tanks, flotation columns and cells, decanters, dewatering systems, thickeners, clarifiers and filters.

Contact with chemicals

Some products and materials used in the processing units are corrosive. So the equipment, tanks, pipes and structures that remain in touch with these chemicals need protection. WEG has product lines developed to withstand conditions such as the transportation and storage of fertilizers, inputs, acids and bases; mixing equipment and mineral electrolytic extraction equipment.

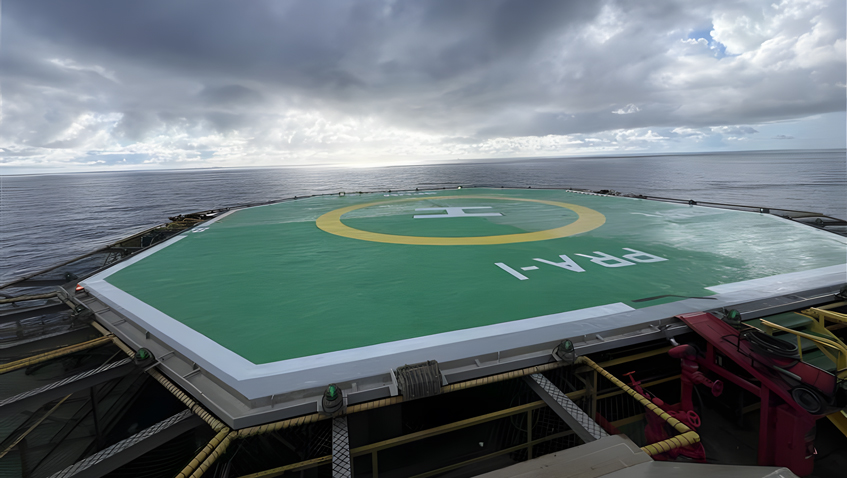

Port, Marine and Aggressive Industrial Areas

Shipping ports where materials are loaded or received are continuously subject to salt spray and humidity, creating one of the most corrosive environments. Factories and processing units in areas with a high concentration of pollutants are also subject to highly aggressive conditions for machinery to operate under.

Learn more about WEG news in Mining.

Are you interested in this solution? Choose one of the options below to find the product you need

Contact us and we will be glad to answer your questions